The “Steel Skeleton” of Cutting Discs: Revealing How Fiberglass Mesh Improves Safety and Performance

When you hold an angle grinder and sparks fly when cutting metal, have you ever wondered why that thin cutting wheel, rotating at high speed, can withstand such centrifugal forces and immense impacts? The secret often lies in its seemingly simple structure. Beyond the abrasive surface and the internal resin, the real unsung hero is the reinforcing mesh sandwiched in the middle: it is the "steel skeleton" of the cutting disc.

Today, as a technical expert at BUDDIES, we take you on an in-depth exploration of this fiberglass mesh, revealing how it becomes the foundation of safety and performance in our line of abrasives.

I. What is Mesh in a Cutting Disc? – Lessons from Reinforced Concrete

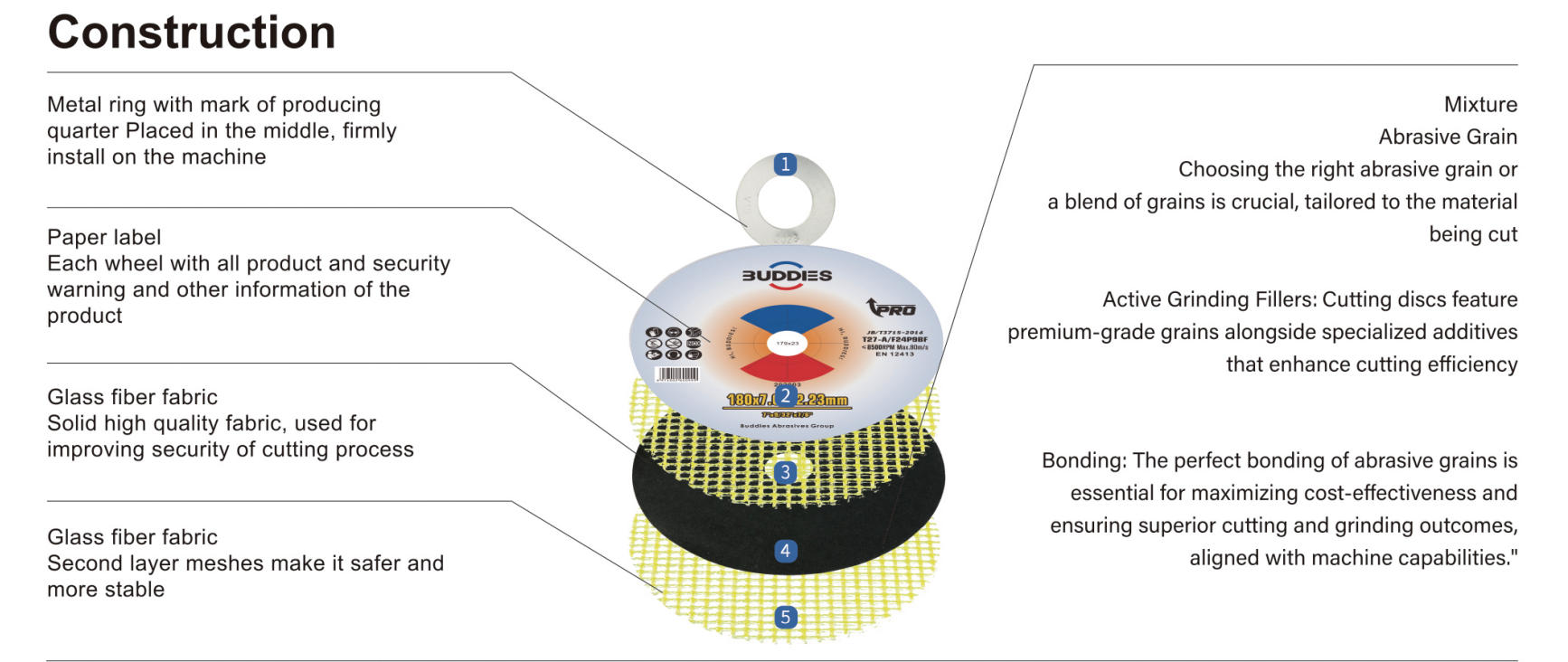

Imagine a cutting wheel as a slab of reinforced concrete: the abrasives (such as aluminum oxide or silicon carbide) act as the tough "concrete" for the cut, while the reinforcing mesh serves as the interlocking "steel bars," providing structural support and reinforcement.

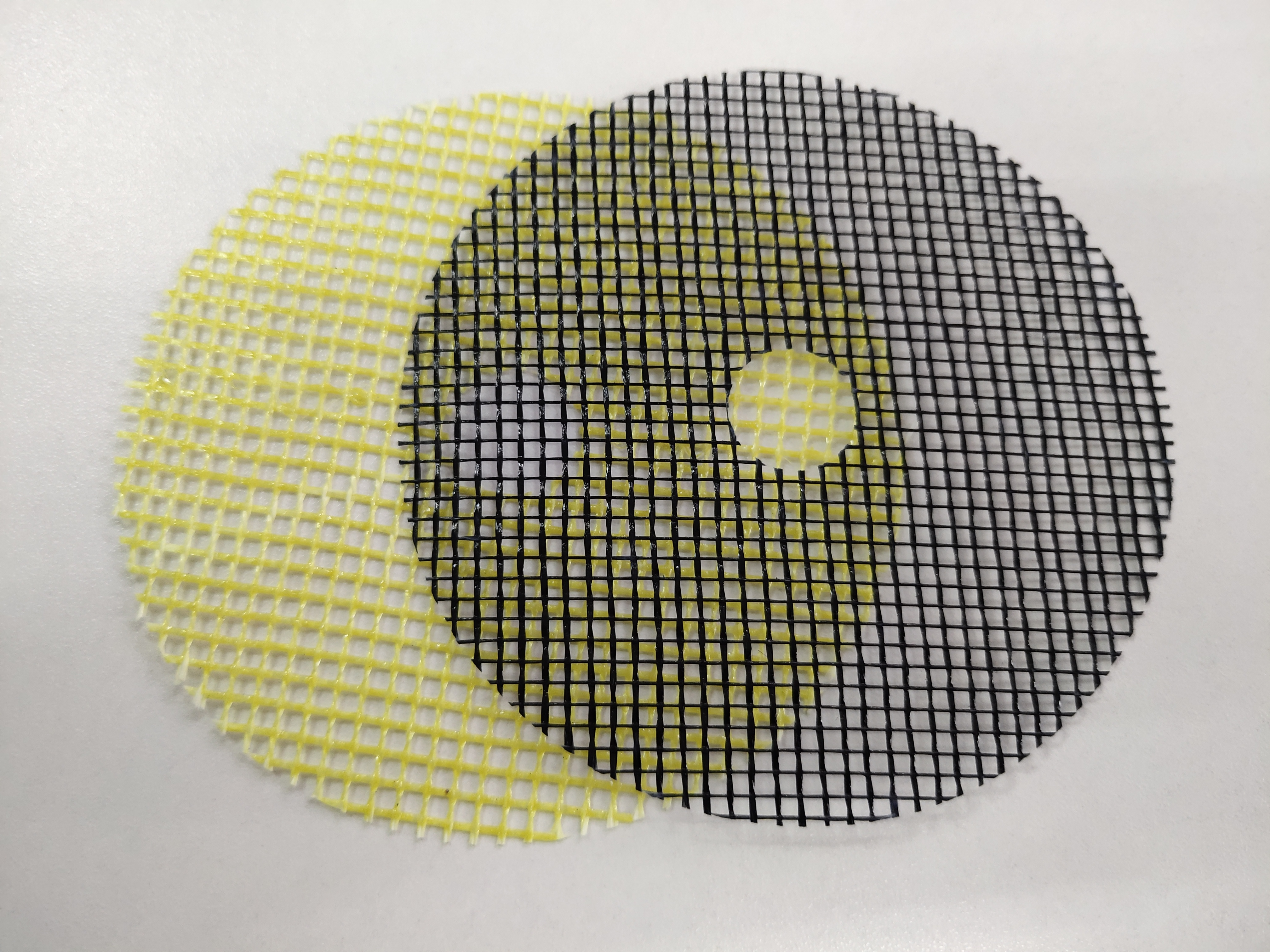

This mesh is typically positioned in the center of the disc, seamlessly integrated with the abrasive layers through advanced manufacturing processes. Its presence transforms the inherently brittle nature of the disc into a high-strength, high-impact composite material.

II. Why is it essential? – The Four Main Missions of Fiberglass Mesh

-

Maximum Security: The Lifeline Against Breakage This is the most critical role of the mesh. Cutting discs operate at speeds greater than 10,000 RPM, withstanding massive centrifugal stresses. Without reinforcement, sudden changes in cutting force or jamming in the workpiece could cause stress concentrations that lead to catastrophic failure. The fragments would scatter like bullets, posing serious risks to operators.

Backed by data: According to European standard EN 12413, cutting wheels must withstand overspeed tests at 1.6 times their rated RPM without failing. The fiberglass mesh is key here, absorbing and distributing stresses effectively. Even in rare breakage scenarios, it binds the fragments together, preventing dangerous projectiles and maximizing operator protection.

-

Mechanical Strengthening: Withstands Higher Speeds and Pressures The fiberglass mesh has exceptional tensile strength, acting as a resilient fishing net that supports the brittle abrasive layer. This allows the discs to tolerate higher operating pressures and rotational speeds, ideal for demanding industrial tasks. At BUDDIES, our heavy-duty cutting discs incorporate high-weight, high-density meshes to ensure unwavering stability during long, intense use.

-

Improved User Experience: Reduction of Vibrations and Deformations A single-layer mesh provides basic reinforcement, but for harsher conditions, double-layer or multi-layer composite structures excel. Increasing the layers significantly improves the rigidity of the disc, controlling vibrations and oscillations at high speeds. Benefits include:

- Precise Cut : Less deviations in the groove for cleaner results.

- Comfortable handling : Less fatigue in the operator's hands.

- Less Tool Wear : Smoother on angle grinder bearings, prolonging the life of the machine.

-

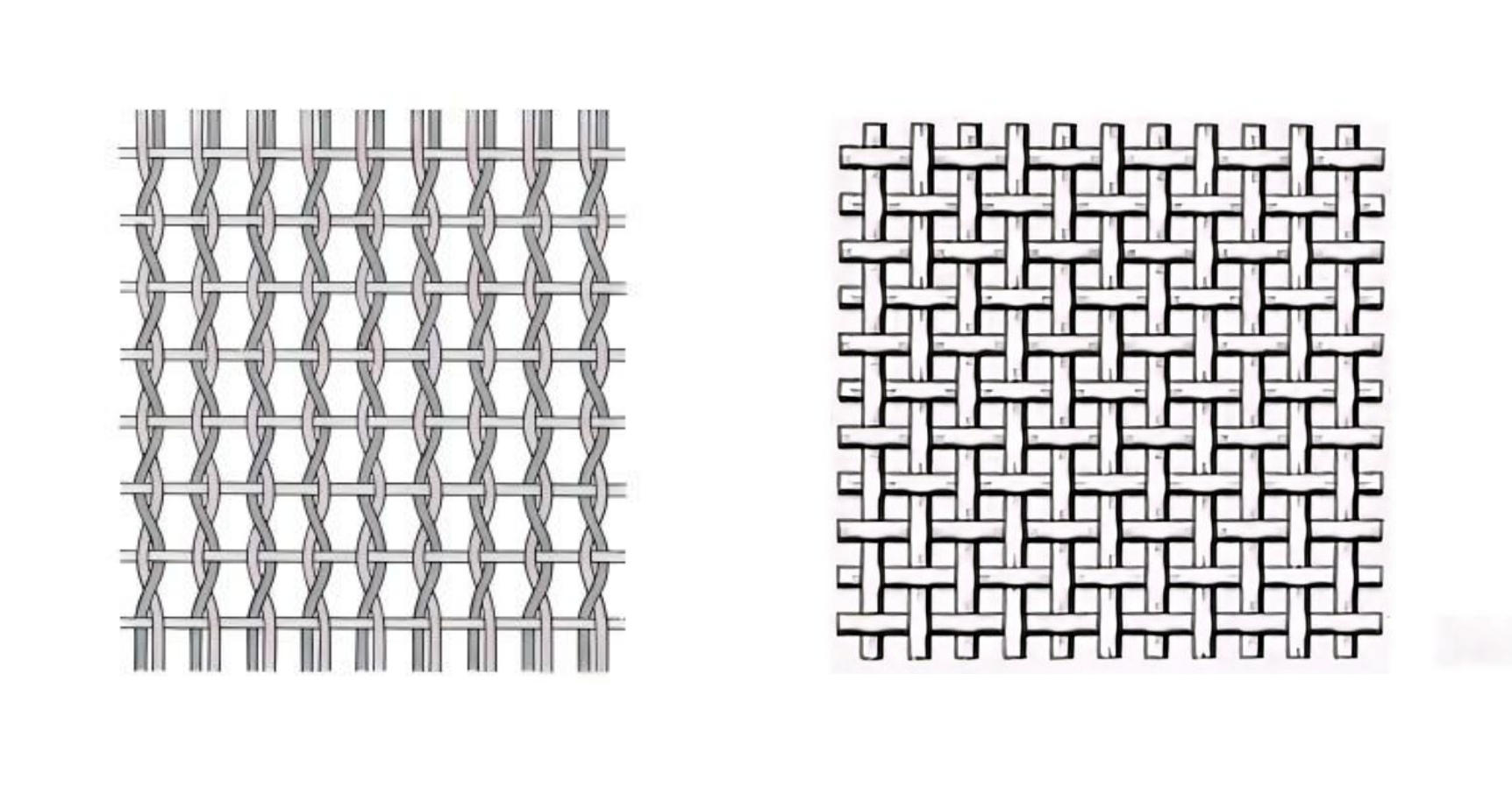

Assistance in Heat Dissipation and Chip Removal The open mesh structure is not completely dense, creating tiny channels for airflow and debris expulsion. This helps mitigate heat buildup in the cutting zone, extending blade life and maintaining efficiency.

III. Materials and Layers: BUDDIES Engineering Choices

What materials are used for the mesh?

Fiberglass : The undisputed leader in cutting discs, offering unmatched advantages:

- High Tensile Strength : Individual strands reach 1,000-3,000 MPa—2-3 times that of common steel.

- Superior Heat Resistance : Withstands prolonged exposure to 550°C and short bursts above 700°C, perfectly adapted to the intense heat of cutting.

- Excellent Insulation : Prevents electrical risks during operation.

- Corrosion Resistance : Antirust and durable in various environments.

Low-cost alternatives like cotton thread or nylon mesh fail in strength and heat tolerance, posing real safety risks. All BUDDIES cutting discs—from our PRO series to everyday options—use premium fiberglass meshes for unbreakable safety.

Other materials, such as polyester or nylon, appear in ultra-thin discs for handling and molding support, but pale in mechanical reinforcement compared to fiberglass.

How to Choose the Number of Mesh Layers?

The layer count is directly linked to the degree of performance and application. BUDDIES designs align with this engineering principle:

- Single Layer Mesh : For standard uses such as DIY projects or cutting low carbon steel—essential safety and basic strength at an economical price.

- Double Layer Mesh : The brand of professional and industrial discs, providing superior rigidity, resistance to bending and protection against ruptures. Ideal for frequent, heavy-duty tasks such as construction sites, metal fabrication or stainless steel work. Our PRO series of BUDDIES features predominantly double-layer fiberglass structures for elite performance in adverse conditions.

- Multilayer/Special Structures : For large diameters (≥400 mm) or specialized applications, complex multilayer reinforcements counteract exponentially greater centrifugal forces.

IV. The Hidden Craftsmanship: The Signature Touch of BUDDIES

Premium mesh is just the start; The true excellence lies in fusing it with the abrasive layers. BUDDIES employs specialized resin impregnation and automated pressing systems, ensuring that the resin fully saturates each fiberglass strand for a flesh-and-blood-like chemical bond. This adhesion remains strong even under extreme tests, unlocking the full potential of the mesh's "steel skeleton."

Conclusion: Your Security, Our Foundation

When selecting cutting wheels, look beyond price and aesthetics—the invisible fiberglass mesh sets the baseline for safety and the ceiling for performance. Although it does not cut directly, it is the silent guardian that ensures that each cut is smooth, efficient and safe.

At BUDDIES, safety is our vital essence. From selecting high-strength fiberglass cloths, to optimizing single- and double-ply designs, and refining precision manufacturing, every disc we produce boasts a reliable "steel skeleton." Because we understand: the tools in your hands connect not only materials, but a commitment to professionalism and responsibility. Explore our range of cutting discs, flapping discs, abrasive belts and angle grinders at buddiesabrasives.com—empower your projects with BUDDIES today.

英语

英语 西班牙语

西班牙语 中文简体

中文简体