The Essential Guide to Backing Fabrics: Creating Superior Sanding Belts for Precision Grinding

In the world of abrasive tools, sanding belts stand out as versatile workhorses for everything from metal polishing to woodworking. But what makes them durable, flexible and efficient under intense pressure? The answer lies in its base structure: the backing fabric. Often overlooked, this critical material determines how well a belt performs during cutting, grinding or finishing tasks. As a leading exporter of cutting discs, grinding wheels, sanding belts, sandpaper and angle grinder accessories, we have seen first-hand how the right backing fabric can elevate product quality and customer satisfaction.

This guide delves into the characteristics of backing fabrics used in coated abrasives such as sanding belts. We will explore material types, historical innovations, key performance factors and practical selection criteria. Whether you are a manufacturer optimizing production or a buyer looking for reliable tools, understanding these elements ensures you get the most from your abrasives. Let's break it down step by step.

Why Backing Fabrics Matter in Sanding Belts

The backing fabrics provide the structural support for the abrasive grains in the sanding belts. Unlike rigid bases, these fabrics offer flexibility, allowing the tape to conform to curved surfaces without cracking or tearing. They must resist high tensile forces, withstand the heat generated by friction, and bond flawlessly with adhesives and grains.

Common materials include cotton, polyester, and blends such as cotton-polyester blends. Cotton remains the preferred choice for its affordability and ease of processing, while synthetics address limitations such as poor water resistance. The choice depends on the application: heavy-duty industrial grinding belts favor robust polyester, while lighter polishing tasks suit cotton.

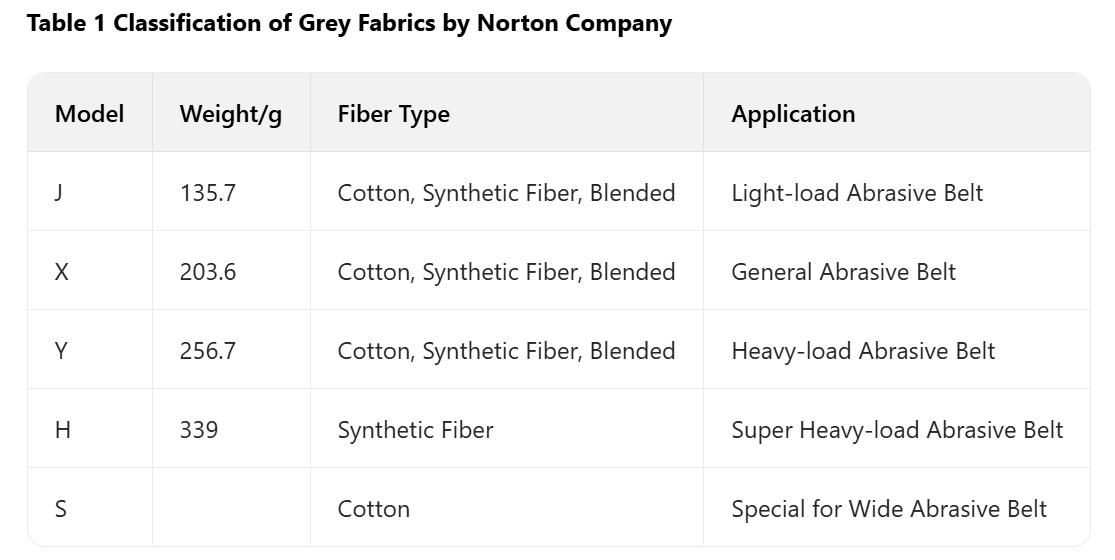

Globally, backing fabrics vary by weight and weave to match grain sizes and workloads. Heavier fabrics excel at coarse grits and aggressive sanding, distributing force evenly to prevent premature wear. The lighter ones shine in fine grains, offering a smoother finish without excessive flex. Standards differ by region: American manufacturers might grade by grams per square meter (gsm), while European standards focus on tensile strength, but the principle is universal: tailor the fabric to the job for optimal longevity and efficiency.

Evolution of Backing Fabrics: From Cotton Classics to Synthetic Powers

Cotton has dominated backing fabrics since the early days of coated abrasives, thanks to its natural advantages. Obtained abundantly and cost-effectively, cotton fabrics provide a smooth, uniform surface that bonds well with resins, glues and grains. Their high flexibility prevents buckling during tape flexing, and they offer solid tensile strength with minimal elongation under load.

However, cotton's disadvantages—such as its lower resistance to water and heat—fueled innovation. In the 1960s, the United States pioneered nylon-based sanding belts, marketed as Microlon, which increased grinding efficiency by approximately 20 times compared to traditional cotton versions. This advancement was due to nylon's superior durability in wet conditions and high-speed operations.

In the 1970s, polyester fabrics emerged as a game changer. With higher tensile strength, lower stretch rates, and better heat and moisture resistance, polyester enabled heavier-duty tapes for demanding applications such as finishing aerospace parts or automotive metal machining. The Norton company's polyester-backed tapes quickly gained popularity worldwide, driving rapid adoption.

Today, polyester represents 7-8% of backing fabrics in coated abrasives in developed markets, with the United States reaching 13.5% as early as 1981—a figure that has continued to increase (source: Coated Abrasives Manufacturers' Institute Industry Reports, 1982). Blends, particularly cotton-polyester blends introduced using Japanese and Korean technologies in the late 1990s, have increased in popularity in China and beyond. These hybrids combine the processability of cotton with the tenacity of polyester, offering thick, flat fabrics at competitive prices.

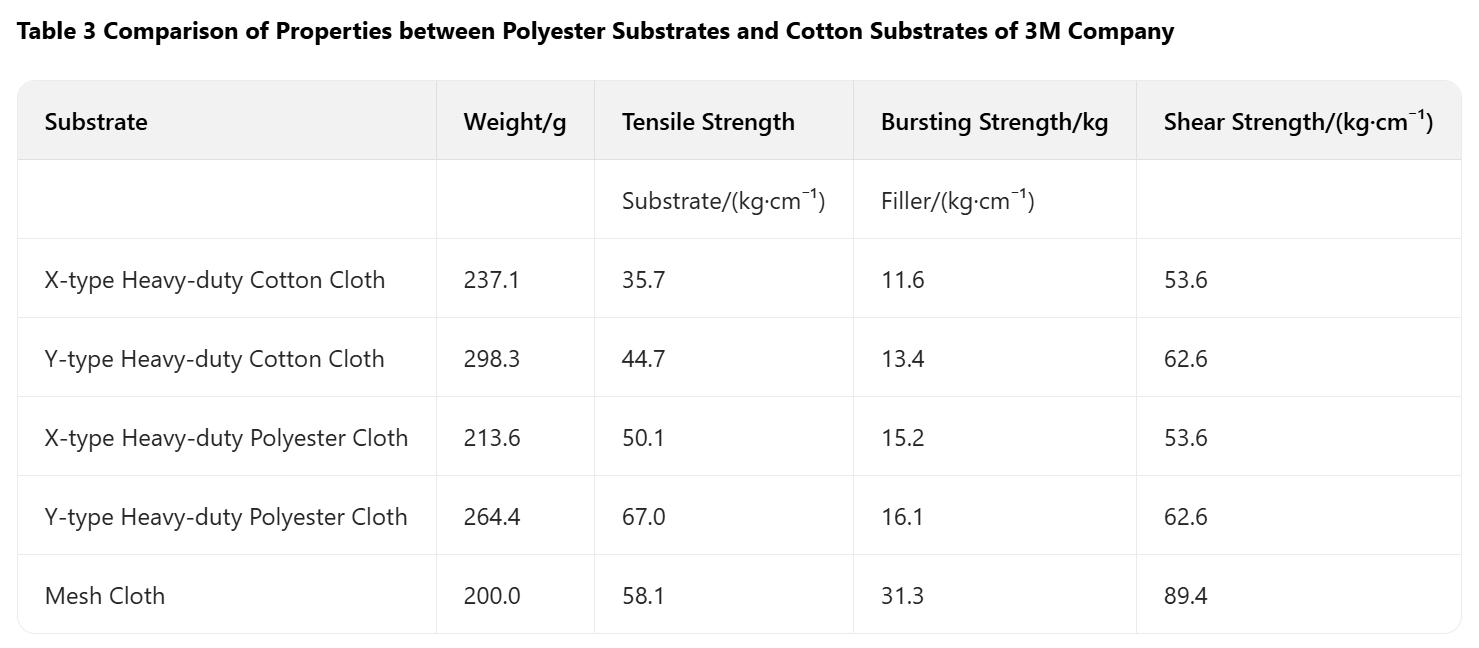

To illustrate the improvement, consider the physical properties of the 3M company data on cotton versus polyester backings:

These metrics highlight why polyester dominates in high-load scenarios: less stretch means precise control, while low water absorption prevents delamination in humid environments.

Key Requirements for High Quality Backing Fabrics

Selecting the right backing isn't a guessing game - it's guided by precise specifications tailored to the performance of the sanding belt. Here we show you what to prioritize:

Fiber Type: Balancing Strength and Compatibility

Cotton reigns supreme in 80-90% of coated abrasives due to its prowess in bonding with various adhesives, flat surface for uniform grain coating, high strength with low stretch and low cost. It is ideal for standard dry sanding. Synthetic options like nylon or polyester come in for specialized needs. They offer smoother surfaces and unmatched strength, but they can elongate more and require selective adhesives—for example, animal glues do not adhere well to synthetic glues. Advances in pretreatments, such as high-temperature stretching, have minimized these problems, making polyester a staple for waterproof tapes. Cotton-polyester blends address mixed demands: cotton helps adhesion, while polyester boosts durability. In China, these have proliferated since the 2000s, but their processing requires dual treatment methods to manage the different fiber affinities—cotton needs saturation for glue absorption, polyester favors surface activation.

Cotton and Quality Blend

For cotton-dominated fabrics, fiber quality is non-negotiable. Premium long-staple cotton—fine, mature and free of impurities—produces denser, whiter, stronger fabrics with minimal knots. This results in tapes that resist tearing during aggressive uses. In blends, fiber ratios matter: a 60/40 cotton-polyester blend could optimize cost and strength, but the ratios must align with the end use. Poor mixing leads to uneven wear, so rigorous testing is essential.

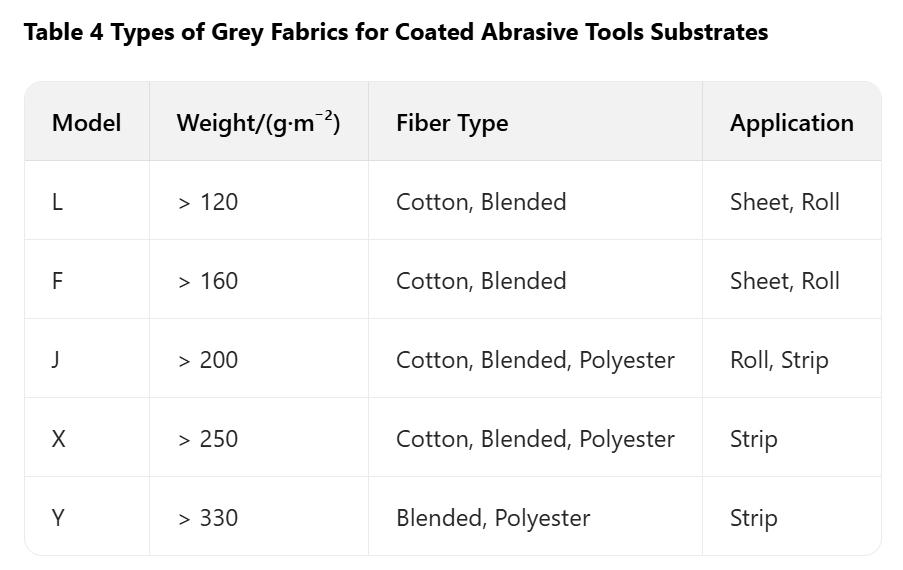

Grading by Weight: Adapted to Grain and Task

Like paper backings, fabric weights are graduated for specific roles. Heavier weights (e.g. 300-500 gsm) accommodate coarse grits (16-60) in power grinding, absorbing impacts without fraying. The lightest ones (150-250 gsm) fit fine grits (120 gsm) for polishing, ensuring flexibility without sinking. Ratings vary: US standards may use "J" for medium-heavy (based on FEPA standards), while others reference ISO weights. For sheet abrasives, lighter fabrics are sufficient; The tapes demand the heaviest ones for tear resistance. Always consult manufacturers' charts for exact matches.

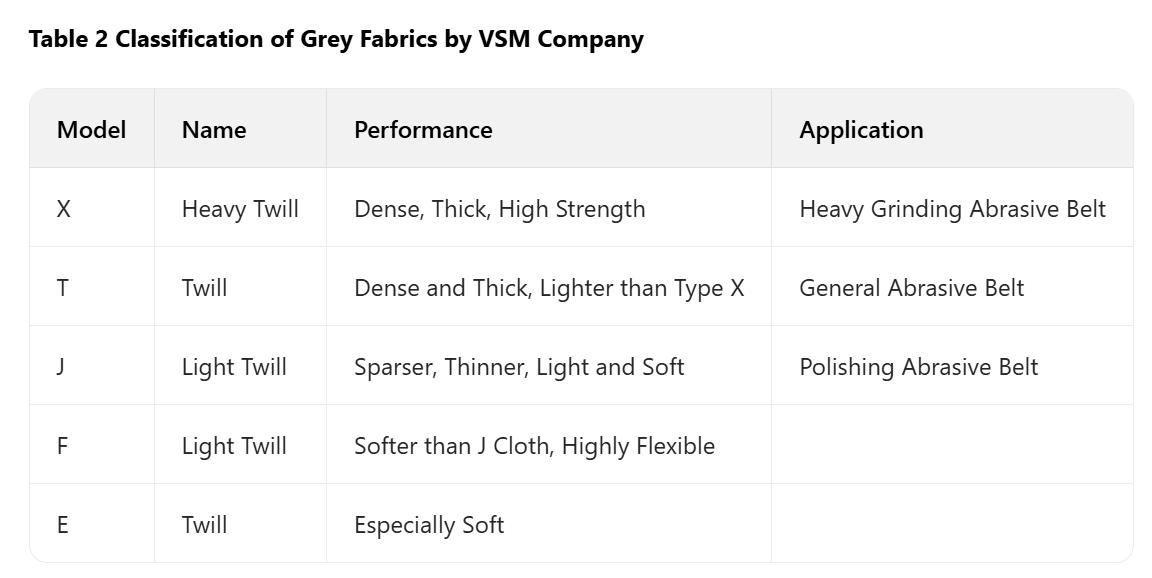

Knitting Structure and Thread Count

Twill weaves dominate with their balance of thickness, softness and strength—perfect for embedding grains without compromising flexibility. Finer twills (higher thread counts, thinner threads) produce elegant surfaces for fine grain tapes, ideal for mirror finishes on metals. Thicker twills (lower counts, thicker threads) handle rough sanding, providing bulk for durability. Plain weaves occasionally appear in ultra-fine applications because of their flatness, aiding polishing on delicate substrates such as composites.

Density, Strength and Elongation: The Performance Triad

Optimal density strikes a middle balance: too dense, and the fabric hardens, hindering glue penetration; too loose, and it weakens, absorbing excessive adhesive. Aim for balanced fabrics that maintain softness along with robustness. A high warp density with a lower weft density promotes radial strength for tape tension, while easier weft tearing simplifies sizing in production. Low elongation (less than 10%) is crucial—elastic fabrics distort under load, leading to uneven abrasion and tape failure.

BUDDIES Professional Perspective: Engineering Wisdom in Backing Material Selection

At BUDDIES, we firmly believe in the industry truth that "backing sets the ceiling, while abrasives unlock performance." Our technical team recommends:

For metal machining and standard woodworking, premium twill cotton fabrics offer reliable solutions with excellent flexibility and cost-effectiveness.

In humid environments or coolant-intensive operations, polyester backings exhibit superior stability, resisting delamination and maintaining integrity.

For heavy-duty grinding and high-volume production, advanced synthetic fiber backs ensure efficiency, minimizing downtime and maximizing performance.

We maintain rigorous supplier control and incoming inspections to ensure that each roll of sanding belt backing meets our performance standards. Our experts are always available to offer personalized backing selection advice, helping you match the ideal sanding belt to your specific workpiece materials, machinery configurations and precision needs. Partner with BUDDIES today—let's engineer your next advancement in abrasive performance.

英语

英语 西班牙语

西班牙语 中文简体

中文简体